Swedish Covenant Diagnostic Radiologist Dr. Aswin Krishnamoorthy holds a plastic replica of a human foot and shows where bone deposits have created a large overgrowth. The surgeon who will operate to remove the overgrowth can use the model to rehearse exactly how much bone needs to be shaved off before he makes an incision, shortening the procedure as well as patient anesthesia time, and most importantly, tailoring the process to that individual’s unique anatomy.

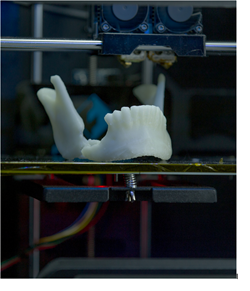

Although 3D printing technology has been around since the 1980's, its use in health care is just beginning to take off. The process involves taking a CT or MRI image of any body part that can be scanned, and translating those images through a software program into digital data that can be “read” by a 3D printer to create plastic models of the body part.

Although 3D printing technology has been around since the 1980's, its use in health care is just beginning to take off. The process involves taking a CT or MRI image of any body part that can be scanned, and translating those images through a software program into digital data that can be “read” by a 3D printer to create plastic models of the body part.

“We could use this routinely,” Krishnamoorthy says. “It’s a unique opportunity for Swedish Covenant Hospital—not many places in Chicago are doing this and those that are don’t have a 3D printer dedicated for hospital use, with professionals who have the anatomical knowledge to make the models come out exactly right.” Krishnamoorthy has that knowledge, and wants to share what he’s learning from the 3D printer more widely with his colleagues because “it provides the opportunity to rehearse surgery before you go in.”

The 3D printer contains spools of polylactic acid (PLA), a biodegradable thermoplastic polyester, or bioplastic, that builds the models layer by layer, a process called additive manufacturing. Using translated data from MRI or CT scans, models take between four to 24 hours to create, depending on the body part, Krisnamoorthy says. However, they can save valuable time during surgery. For example, in the foot model, it illustrated that more time would be needed to remove the bone growth than the surgeon had originally thought, allowing him to optimize the procedure and corresponding OR time accordingly. 3D models allow clinicians to get the most out of non-invasive imaging, so they can more specifically target procedures and improve results.

“It's a useful way to communicate.These models not only help physicians and surgeons better prepare and plan procedures, they give them a great new tool for explaining to patients what they plan to do, and what patients can expect from their post-surgical treatment course.”

Krishnamoorthy has been experimenting with the 3D printer since May and has made models of the jaw, spine and some extremities. In the future, if the models could be produced under sterile conditions, they could be used to create custom-made replacement body parts, since they are completely resorbable, he adds.

“The power of this technology is tremendous,” he says. “It allows for more creativity and a more complete view into the body. Being early adopters of this exciting technology allows our physicians to have tremendous insight into their patients’ anatomy and planned treatment.”

Click here to learn more about Swedish Covenant Hospital's

Radiology Department, or call

773-878-6888 to schedule an appointment for Radiology Services.